- Home

- New Equipment

- Sprayer

- 2000L Gregoire Speedflow Progress Sprayer

1500L Gregoire Powerflow VTD Sprayer

June 4, 2019

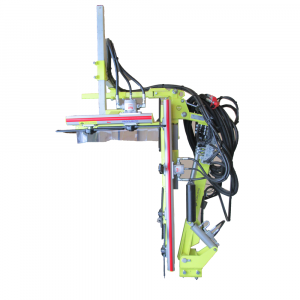

Collard P1100Z Single L Trimmer/Hedger

June 4, 20192000L Gregoire Speedflow Progress Sprayer

-

Air velocity, precision and versatility

-

Face-to-face spray in 2 or 3 complete rows

-

Row widths from 1.50 to 3m

SPEEDFLOW sprayers consist of a lightweight, simple and robust tubular frame. Axles placed in the middle position, adjustable to the track of the tractor, offer an excellent load transfer. Maneuverability is increased thanks to the articulated articulated drawbar. SPEEDFLOW PROGRESS is equipped with a smooth polyethylene tank respecting the trellising. The rinse tank and the hand basin are integrated in the main tank. This range comes in several pot capacities to meet your needs. The product to be sprayed follows a circuit designed and carefully optimized by our developers. You deposit the product in an induction sieve which will then pass through a low pressure filter. It circulates thanks to a 4-piston diaphragm pump with sufficient capacity for optimal feeding of the circuit and effective mixing. Then the arrival at the regulation and distribution ramp is carried out through a high-pressure filter. The control and distribution commands vary according to the model: DPAE for an automatic management of the contribution of the product, or a manual regulation. For row widths from 1.50 to 3m, Speedflow Progress, pneumatic ramp face-to-face in 2 or 3 complete rows, is equipped with the FLEXIspray system: flexible, unbreakable hangers, light because inflated thanks to the distributed air so homogeneous by a volute 6 polyethylene outlets and expelled by a turbine of 520mm in diameter to become rigid and be kept vertical in the row. Dynadiff diffusing nozzles increase air velocity, product is well distributed, droplet formation is optimized, and spray quality is excellent.